Hellion 45 Suppressor Resources

Thank you for considering or purchasing the Shaw Armament Systems ThunderCan Hellion 45 Suppressor.

The Shaw Armament Systems ThunderCan Hellion 45 is a purpose built .45 caliber handgun suppressor delivering excellent sound reduction and tone in a lightweight package. Constructed of a combination of aluminum and titanium, it achieves an excellent balance of size and weight to durability for your 45 caliber applications. Compatibility with 1.203”x28 mounting solutions gives the end user multiple options for attaching the suppressor to the host platform by utilizing an external booster, quick detach systems (including 3 Lug), or direct thread mounts. The Hellion 45 is a fully user serviceable suppressor with trouble-free disassembly for maintenance and cleaning.

Below are resources and instructions to help you understand and keep your new ThunderCan Suppressor functioning at its peak performance.

SPECIFICATIONS

LENGTH: 8.1 in (no mount)

DIAMETER: 1.36 in

WEIGHT: 8.7 oz (no mount)

CALIBER: Pistol Calibers up to .45 (including 10MM), 300 Blackout Subsonic

MATERIAL CONSTRUCTION: Grade 5 Titanium, 7075-T6 Aluminum

FINISHES: Black High Temp C Series Cerakote, Black Type III Hardcoat Anodizing

BARREL RESTRICTIONS: 45 ACP – None, 300 Blackout Subsonic – 8”

DURABILITY: Limited Full Auto

MOUNTS: 1.203”x28 Mount Compatible / Offered with Booster Assembly and .578x28 Piston or with no mount

DISASSEMBLY & ASSEMBLY OF YOUR THUNDERCAN SUPPRESSOR

A step-through guide on how to disassemble your Thundercan Suppressor.

CLEANING YOUR SUPPRESSOR

How to clean your ThunderCan suppressor.

LIFETIME WARRANTY

SAS provides a limited lifetime warranty against all manufacturing defects on all products manufactured by SAS. Warranty Information.

QUESTIONS?

Contact Shaw Armament Systems or 678-915-2075, M-F: 9 am-5 pm.

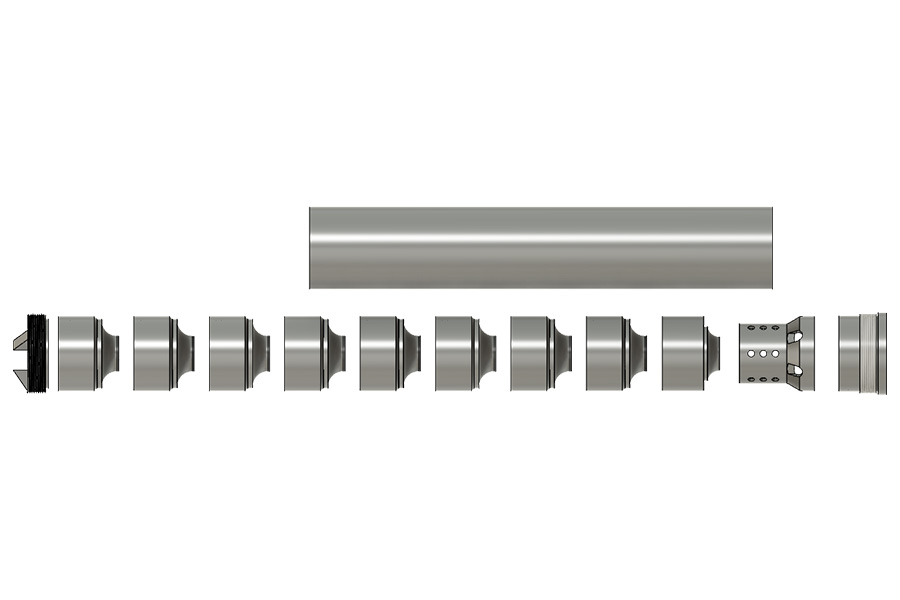

COMPONENTS OF YOUR THUNDERCAN HELLION 45 SUPPRESSOR

Use the Hellion 45 assembly drawings to identify components and understand maintenance and servicing steps.